TAKAMAZ New XT-8MY 8 inch CNC 1 Spindle 1 Turret Precision Lathe

Supports machining of long shafts up to 300 mm in length. Square slideways are adopted on all axes to give a highly rigid structure. While a tailstock specification can also be selected, we have achieved the smallest floor space in its class, being about 20% smaller than our competitors.

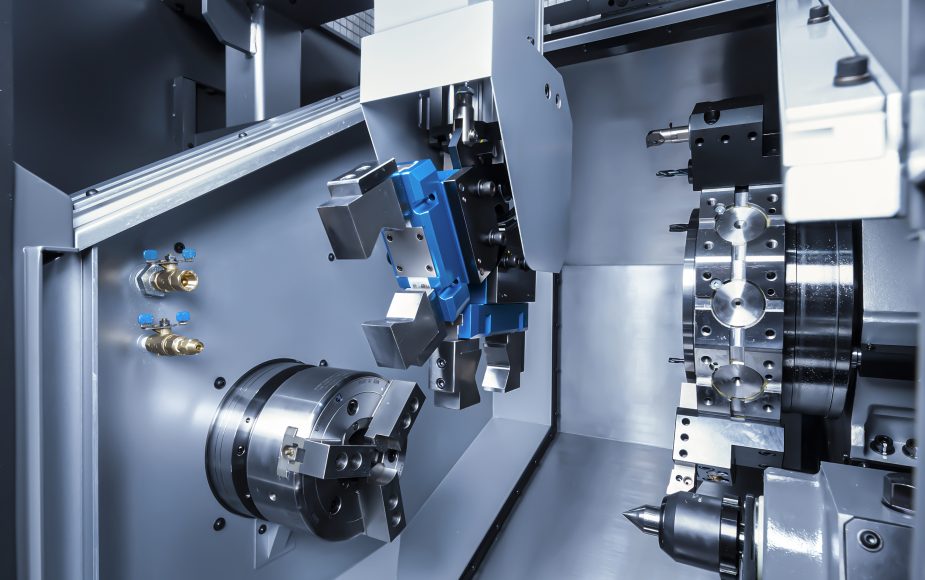

The milling unit with a motor output of AC 5.5/3.7/2.2 kW and a maximum tool size of φ20 mm improves productivity. The turret uses the bolt mount system (BMT55), which can shorten the setup time. In addition, the turret half-indexing mechanism allows up to 24 tools to be mounted, also reducing set-up time (up to 12 power tools can be mounted). In addition, the rapid traverse of the C-axis and the indexing accuracy of the spindle have been improved to achieve high productivity. By using power tool, it is possible to consolidate a wide variety of processes such as drilling, drilling using an end mill, and grooving into one machine.

To improve user-friendliness, both the machine and automation equipment are controlled centrally through FANUC operations. We provide an automation system offering peace of mind and reliability, including more efficient set-up work with the handle retrace function.

In addition to the conventional FANUC screen, functions optimal for automated machines are featured. A support function is added to enable safe and easy manual cutting work for tool alignment, and also there is the traceability function that automatically saves the operating status to assist with preventive maintenance.

A wide range of units from tailstock attachments such as servo-driven tailstocks and built-in tailstocks to steady rests are available to assist with various kinds of machining. Demand for compound processing of shaft work is increasing, so it is necessary, and it could use for motor-related parts and drivetrain parts for hybrid cars and electric vehicles, etc.