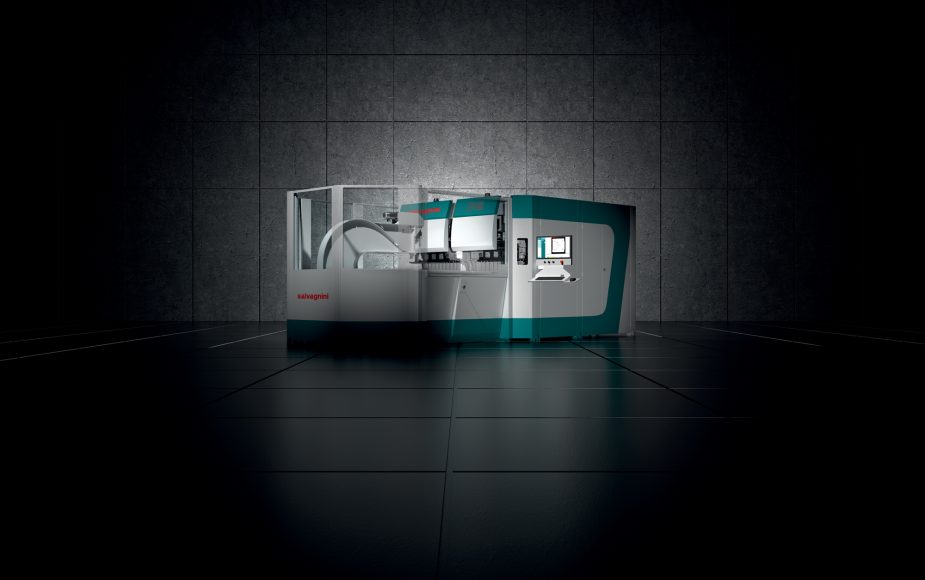

SALVAGNINI ITALIA At EMO MILANO 2021 Salvagnini will show the P2-2120 panel bender

At EMO MILANO 2021 Salvagnini will show the P2-2120 panel bender equipped with the new CUT, the option to sequentially cut one or more profiles starting from a single notched sheet with different lengths.

P2 is one of the most successful models of panel bender, as it works with universal bending tools that require no machine stops or set-up times, and automatically adapts to material variations, ensuring consistent quality of parts in a wide range of cold-rolled steels thanks to the proprietary MAC3.0 technology. P2 does not require the intervention of an operator during the cycle, guaranteeing maximum safety, as bending and manipulation are automatic operations, while loading/unloading are manually managed. The P2 features extremely low consumption thanks to the direct drives that require just 3 kW in cycle and only 0.5 kW in stand-by.

The new CUT option is a distinctive feature of the Salvagnini P4 panel benders and includes a CUT blade, that lies on top of the lower bending blade of the P2, used to make the separation cut of the bent profile; a cutting tool with a fixed composition that acts as the upper cutting blade; a conveyor that transfers the cut part to the automatic shutter for manual extraction. Parts are made in multiples as they are associated on the same strip of material, which is bent and cut in a single process and this contributes to increase overall process efficiency. In terms of feasibility, the CUT tool can be considered an advantage with parts that are too small or too narrow to be bent on a press brake. This option expresses its fullest potential in the sectors using many profiles such as perimeter profiles, mounting brackets, like HVAC, subcontracting, catering, electrical goods and metal furniture.