TEBIS Tebis 4.1 is a complete parametric/associative CAD/CAM solution – especially for manufacturing individual machine

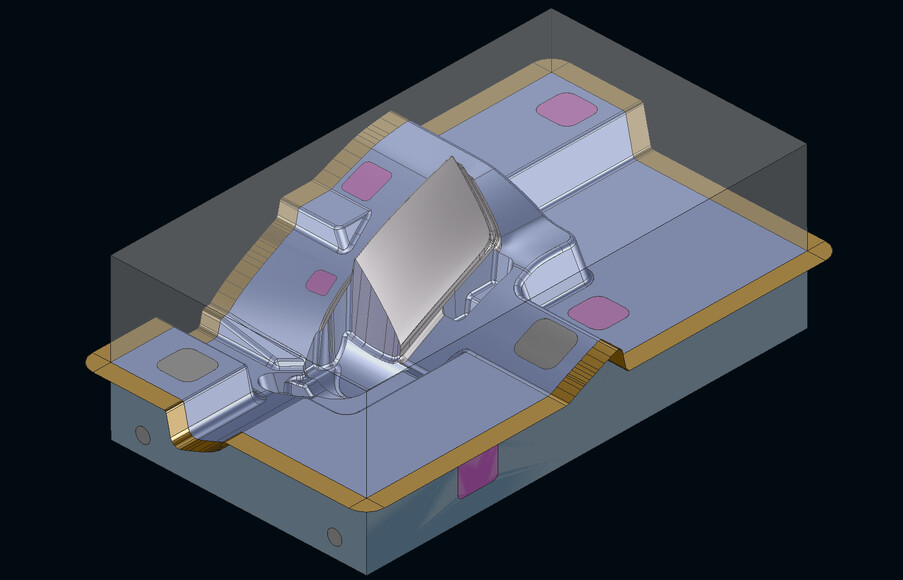

The newly developed parametric/associative system base is specifically designed to the requirements of single-part and small-series manufacturing, where everyday challenges include precarious delivery deadlines, frequent part changes, many variants and fluctuating levels of data quality. In contrast to many other CAD systems, the robust nature of Tebis 4.1 means that it does not distinguish between surfaces and open or closed solids. The user benefits from this and saves a lot of time: All objects can be combined without resulting in error messages – even if there are gaps in the surface topology. CAD activities can be structured and standardized using templates.

Tebis 4.1 provides all the necessary prerequisites for safe, fast and reduced-personnel production and used for automation of all manufacturing processes.

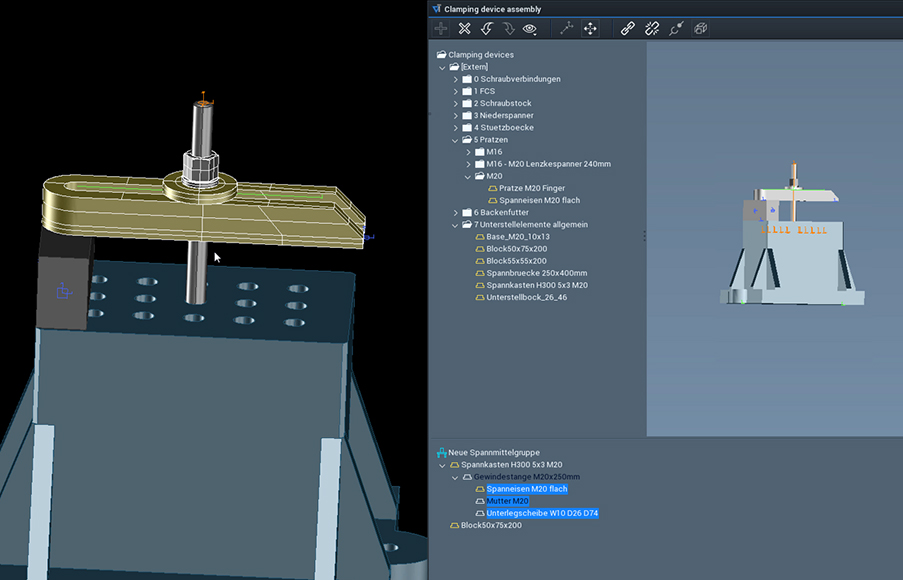

The proven virtual process libraries, in which the details of real machine components are represented in the form of digital twins, have been supplemented with the new clamping device library. This enables the NC programmer to realistically perform a virtual setup of their part on the machine, providing another benefit for process safety. All relevant information is transferred with the NC documentation to the person responsible for setup.

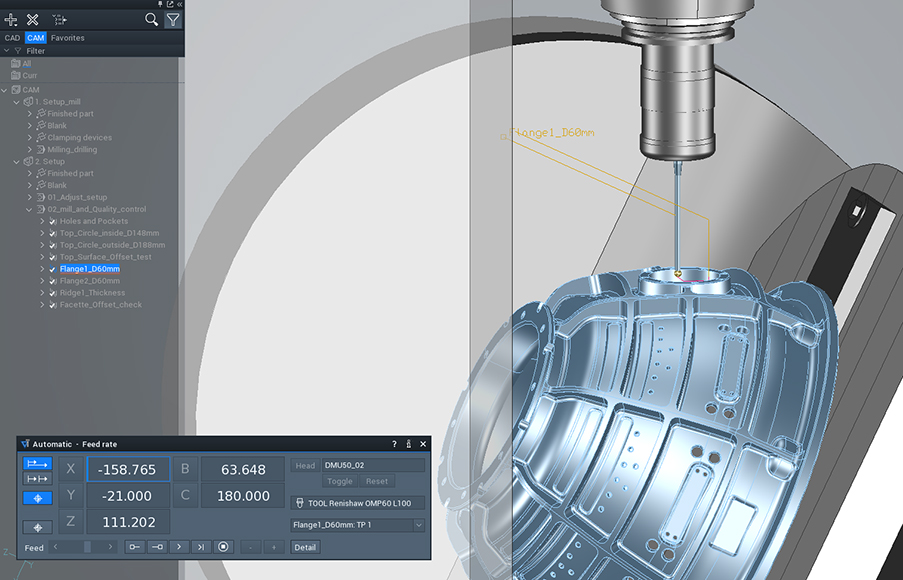

NC programmers and machine operators can now also fully integrate all measurement tasks in the digital manufacturing process with Tebis 4.1. This enables a direct check in the CAM system if the part is correctly clamped and the blank is correctly dimensioned and oriented – ensuring shorter setup and machining times, higher part quality and fewer correction iterations.

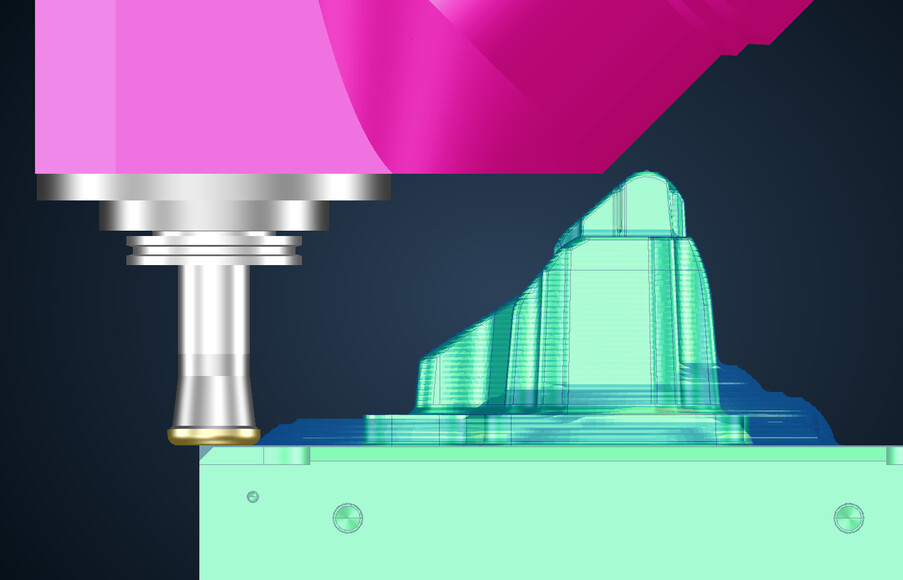

For even greater safety, the machine head is accounted for digitally during NC calculation. Tebis detects potential collisions with the machine head and prevents these by reducing the affected milling areas. Unlike other CAM systems, the check is performed using the real head geometry instead of a substitute geometry.